Unlocking the Future: The Essential Role of Cell-Cultivated Meat Protein

The push for sustainable protein keeps pulling biotechnology into new territory. We’ve watched momentum build around cell-cultivated meat, a way to produce meat that aims to cut environmental impact while avoiding animal slaughter. It feels like a real shift, grounded in hard science. Our attention is on the protein components that make this possible.

Understanding Cell-Cultivated Meat: A Sustainable Protein Revolution

Cell-cultivated meat, also known as cultured meat or cellular agriculture, involves producing animal meat directly from cells. This process bypasses the need for raising and slaughtering animals. The environmental benefits are significant, including reduced land and water usage, and lower greenhouse gas emissions. Ethically, it offers an animal-friendly alternative to conventional meat. We view cultivated meat as a paradigm shift in how humanity will source its protein. This technology applies advanced biological processes to create genuine meat products.

The Core Science: How Cell-Cultivated Meat Protein is Produced

Producing cell-cultivated meat relies on sophisticated scientific principles. The process begins with sourcing specific animal cells, followed by their proliferation and differentiation in a controlled environment. Cell culture media play an indispensable role, providing the necessary nutrients and signals for cell growth. The protein components within these media are particularly important.

1. Sourcing and Cultivating Starter Cells for Meat Production

The first step involves obtaining a small sample of animal cells. These are usually muscle stem cells or fibroblasts, selected for their capacity to proliferate and differentiate. We then establish stable cell lines from these primary cells. This secures a consistent and scalable source for meat production. Subsequent expansion of these cells occurs in specialized bioreactors.

2. The Indispensable Role of Growth Factors in Cell Proliferation

Growth factors are signaling proteins required for cell growth, proliferation, and differentiation. In serum-free cell culture media, these proteins steer cellular behavior. For instance, FGFs stimulate cell division, while ILs can influence immune responses and cell development. Additionally, TGFs like Activin A regulate cell growth and differentiation. High-quality recombinant proteins are needed to keep culture conditions optimal.

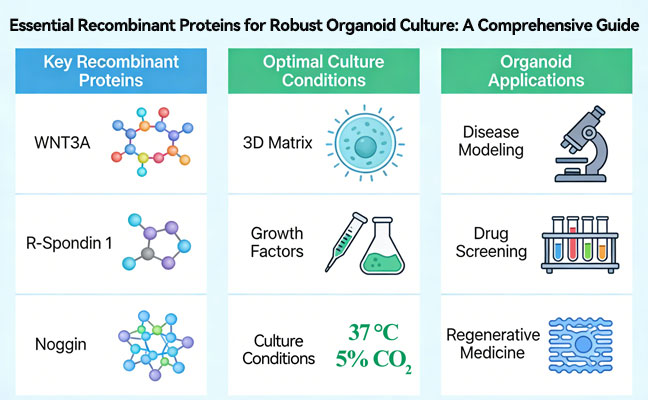

Recombinant Proteins: Powering the Future of Cultivated Meat

Recombinant proteins are central components in serum-free cell culture media for cultivated meat. They offer clear advantages over traditional supplements. Their precise function and consistent quality are vital for the industry’s advancement.

1. Why Recombinant Proteins are Essential for Serum-Free Media

Traditional cell culture often relies on fetal bovine serum (FBS). However, FBS presents several limitations: variability between batches, ethical concerns regarding animal sourcing, and high cost. Recombinant proteins provide a defined, consistent, and ethical alternative. This consistency is key for regulatory approval and for achieving industrial-scale production. Using recombinant proteins strengthens process control and product safety.

| Feature | FBS (Fetal Bovine Serum) | Recombinant Proteins |

|---|---|---|

| Consistency | Low (batch-to-batch variation) | High (defined composition) |

| Ethical Concerns | High (animal-derived) | Low (animal-free production) |

| Cost | Variable, often high | Can be optimized for scale |

| Defined Media | No | Yes |

| Regulatory Path | Complex | Simpler |

2. High-Quality Recombinant Proteins from EastMabBio for Cultivated Meat

Jiangsu East-Mab Biomedical Technology Co., Ltd. specializes in providing high-quality recombinant protein raw materials. Our products are specifically designed for cell culture media used in cultivated meat production. We offer a comprehensive range of cell culture proteins, including various FGFs, ILs, and Activin A. These proteins are produced with high purity and validated bioactivity. For example, our Recombinant Human FGF-2/bFGF is expressed in E. coli with ≥95% purity and an ED₅₀ ≤2.0 ng/mL. Recombinant Human IL-6, expressed in CHO cells, boasts ≥95% purity and an ED₅₀ of 0.2-1 ng/mL. Our Recombinant Bovine/Porcine Activin A, also CHO expressed, maintains ≥95% purity. Our world-class platform ensures reliable and consistent supply, addressing critical needs for scalability and cost-effectiveness in the cultivated meat sector.

Overcoming Challenges and Shaping the Future of Cultivated Meat

The cultivated meat industry faces significant hurdles, particularly in cost reduction, scalability, and navigating regulatory pathways. The high cost of cell culture media components, especially growth factors, remains a primary challenge. Advancements in recombinant protein technology are directly helping to resolve these obstacles. By developing more efficient and cost-effective production methods for these proteins, we can lower overall production costs. This makes cultivated meat more accessible and competitive. The future outlook for the industry depends heavily on continued innovation in this area.

What is cell-cultivated meat protein?

Cell-cultivated meat protein refers to the proteins derived from animal cells grown in a controlled laboratory or industrial environment, rather than from slaughtered animals. These proteins are fundamental components of the final cultivated meat product, contributing to its nutritional value and texture. The process involves taking a small sample of animal cells and providing them with nutrients, including essential recombinant proteins, to proliferate and differentiate into muscle and fat tissues.

Why are recombinant proteins crucial for cultivated meat production?

Recombinant proteins, such as growth factors and cytokines, are vital because they act as signaling molecules that direct cell growth, proliferation, and differentiation in serum-free cell culture media. Unlike traditional fetal bovine serum (FBS), recombinant proteins offer a defined, consistent, ethical, and animal-free alternative, addressing concerns about supply chain variability, cost, and animal welfare. They are necessary for achieving the scalability and regulatory approval required for commercial cultivated meat production.

How does Jiangsu East-Mab Biomedical Technology contribute to the cultivated meat industry?

Jiangsu East-Mab Biomedical Technology Co., Ltd. is a leading provider of high-quality recombinant protein raw materials, which are vital for the cell culture media used in cultivated meat production. Our extensive range of cell culture proteins, including various FGFs, ILs, and Activin A, are engineered to support optimal cell growth and differentiation. With a world-class research and production platform, we help cultivated meat companies overcome challenges related to scalability, cost, and consistency by supplying reliable, high-purity components.

What are the main challenges in scaling up cell-cultivated meat protein production?

Scaling up cell-cultivated meat protein production faces several challenges, including reducing the cost of cell culture media components (especially growth factors), optimizing bioreactor design for large-scale cell growth, ensuring consistent product quality, and navigating complex regulatory landscapes. The availability of high-quality, cost-effective recombinant proteins is a major factor in addressing these scalability and economic hurdles.

Partner with EastMabBio for Your Cultivated Meat Innovations

Discover how Jiangsu East-Mab Biomedical Technology Co., Ltd.’s high-quality recombinant proteins can accelerate your cell-cultivated meat research and production. Contact us today to discuss your specific needs and explore our comprehensive product catalog. Reach us at +86-400-998-0106 or product@eastmab.com.